Aluminum Oil Cooler Remanufacturing

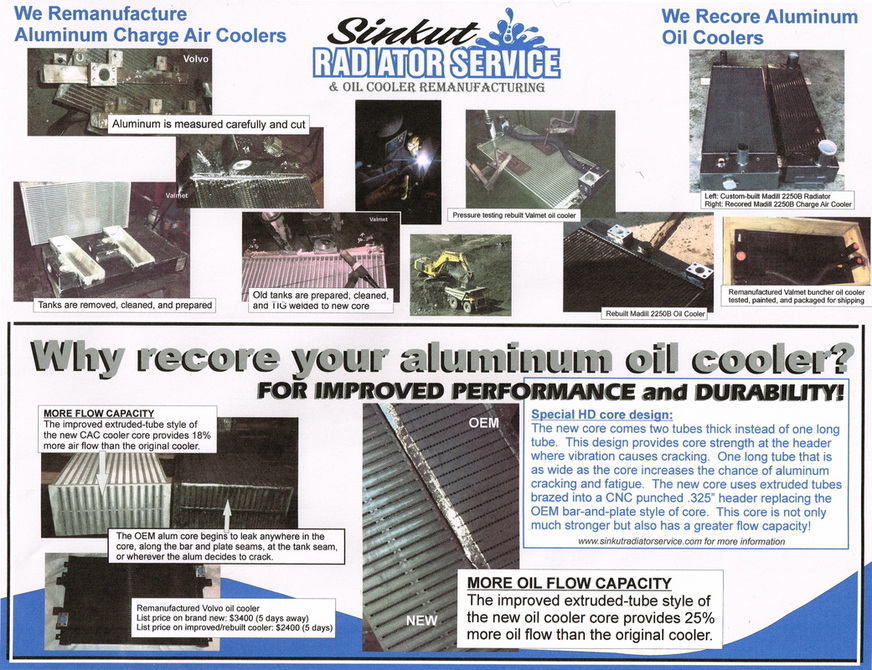

Most hydraulic oil coolers, charge air coolers, and other air-to-air/water heat exchangers found in mining and forestry equipment are aluminum bar-and-plate coolers. We have the skills and the equipment to rebuild your leaking oil coolers with an upgraded extruded tube core. One of the most common oil coolers that we remanufacture is the hydraulic oil cooler for the Madill 2250 buncher. We stock a new oil cooler core for this unit as well as a new core for the Madill 2850 and 3800 loaders. This is perhaps the most exciting phase of our business.

We have several aluminum core suppliers to choose from in North America, with one being located in Eastern Canada. This Canadian supplier is a small family-owned factory that specializes in high-quality craftsmanship and delivers top notch oil cooler cores with extremely quick turnaround times complete with delivery to the closest Air Canada depot. We have found these cores to be the answer to our core supply dilema and we are thankful to be able to work with a company concerned chiefly with quality and production times.

DRF450 Kalmar Reach Stackers: for years we have been remanufacturing the transmission oil coolers on these port terminal handlers. We now have designed a complete drop-in assembly to minimize downtime and provide an improved core design for longer life. We also supply the brand new copper/brass radiator that replaces the aluminum bar-and-plate rad and that is designed to withstand the salt and corrosion found in the port.

Why Rebuild Your Aluminum Oil/Air Coolers?

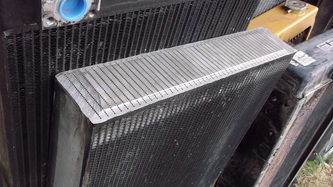

We will improve the core over the OEM design, as shown below, achieving greater cooling capacity, heat transfer efficiency, and overall core strength in the form of improved fin, tube, and header plate designs.

We have two core styles to choose from:

1) OE-style Xbar core (single row, mullti-galleried, extruded tube, bar-and-plate style header) *very similar to OEM, but using extruded tubes*

2) X325 core (2 rows of multi-galleried, extruded tubes, 0.325" thick CNC punched header).

The OE-style Xbar core is an inexpensive, good quality core using extruded tubes versus the bar-and-plate tubes most OEMs (original equipment manufacturer) use.

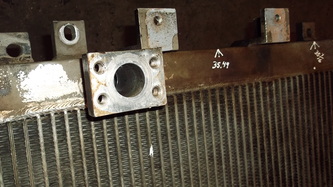

The X325 core is a high quality core using two or more rows of extruded tubes vacuum-brazed into a .325" CNC punched header plate. This core style improves tank to core seam quality/strength, header plate strength (less chance of aluminum fatigue/cracking at header), and increases oil flow capacity by as much as 25-30%.

Click on the pictures below to enlarge and take note of the descriptions in the lower lefthand corners.

We have several aluminum core suppliers to choose from in North America, with one being located in Eastern Canada. This Canadian supplier is a small family-owned factory that specializes in high-quality craftsmanship and delivers top notch oil cooler cores with extremely quick turnaround times complete with delivery to the closest Air Canada depot. We have found these cores to be the answer to our core supply dilema and we are thankful to be able to work with a company concerned chiefly with quality and production times.

DRF450 Kalmar Reach Stackers: for years we have been remanufacturing the transmission oil coolers on these port terminal handlers. We now have designed a complete drop-in assembly to minimize downtime and provide an improved core design for longer life. We also supply the brand new copper/brass radiator that replaces the aluminum bar-and-plate rad and that is designed to withstand the salt and corrosion found in the port.

Why Rebuild Your Aluminum Oil/Air Coolers?

We will improve the core over the OEM design, as shown below, achieving greater cooling capacity, heat transfer efficiency, and overall core strength in the form of improved fin, tube, and header plate designs.

We have two core styles to choose from:

1) OE-style Xbar core (single row, mullti-galleried, extruded tube, bar-and-plate style header) *very similar to OEM, but using extruded tubes*

2) X325 core (2 rows of multi-galleried, extruded tubes, 0.325" thick CNC punched header).

The OE-style Xbar core is an inexpensive, good quality core using extruded tubes versus the bar-and-plate tubes most OEMs (original equipment manufacturer) use.

The X325 core is a high quality core using two or more rows of extruded tubes vacuum-brazed into a .325" CNC punched header plate. This core style improves tank to core seam quality/strength, header plate strength (less chance of aluminum fatigue/cracking at header), and increases oil flow capacity by as much as 25-30%.

Click on the pictures below to enlarge and take note of the descriptions in the lower lefthand corners.

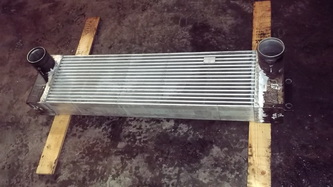

Pics of rebuilt coolers

For more details on why you should consider a Sinkut aluminum rebuild, please take some time and read the brochure below: